The EOS-1 family has won overwhelming trust from many professional photographers. One of the reasons is the high level of durability that is capable of withstanding harsh shooting conditions. Coupled with the extremely light weight, the dust- and moisture-resistant (*1) aluminium alloy body has gained strong support from professionals who are into sports and nature photography. In this article, I will unveil the secret behind the body of the EOS-1 cameras.

The streamline at the top of the EOS-1 camera body is not just part of the design. It serves functional purposes as well.

Integrating Function with Design

For users of the EOS Digital series, you might have heard of the EOS-1V. Released in 2000, the EOS-1V was developed as the highest-end professional model and the successor of the EOS-1N, and remains the flagship model of Canon's 35mm SLR film cameras today (2014). The key features of the camera include 45-point AF, a maximum continuous shooting speed of about 10 fps (*2), a predictive AI Servo AF mode that performs tracking during continuous shooting at about 9 fps (*2), fast shutter speed at 1/8000 and X=1/250 second, and a viewfinder coverage of about 100% in all four directions. These specs remain comparable to those of the digital SLR models today, and are befitting of a flagship model.

Yet another distinctive feature of the EOS-1V is that it is the first Canon camera to adopt the aluminium alloy material for its body, making it the trendsetter for the widespread use of aluminium alloy in the cameras today. The appearance of the EOS-1V left a dramatic impression with the complex curved surface of the camera body and the use of magnesium alloy. The streamline at the top of the body symbolises the design of the EOS-1 family. At the same time, its design resembles that of the EOS-1, which took over the T90 to become the highest-end line among Canon's SLR cameras. Dirt, raindrops and snowflakes can be removed with a single wipe. While the streamlined design boasts both excellent functionality and aesthetics, it also posed a problem.

This is the body of the "EOS-1D X", the latest EOS flagship model that originates from the EOS-1 series. Sealing processes are applied to different parts of the camera, which are combined with the robust magnesium alloy body for enhanced toughness as well as dust and moisture resistance.

The EOS-1 family adopts a highly dust- and moisture-resistant structure that supports shoots by professionals under harsh conditions. (*1)

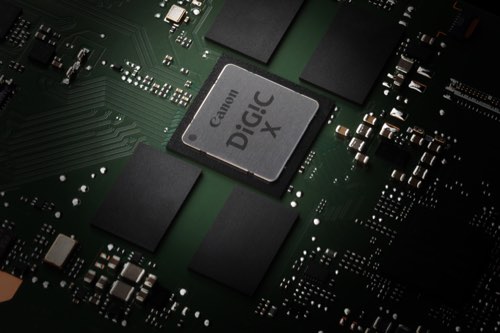

Pursuing Functionality with Cutting-edge Technologies

The EOS-1 and EOS-1N, which used to be the flagship models prior to the EOS-1V, both employed the lightweight and tough polycarbonate for their body. The technologies back then were not able to produce a unique curved surface using metallic materials, although some users were longing for the introduction of a metallic body. This was the reason why Canon set sights on moulding the lightweight and robust magnesium alloy in the same way as plastics through thixomoulding, the latest technology at that time. Thixomoulding is a process that injects magnesium alloy uniformly into the mould, but there did not exist any precedent for fabricating materials into shapes as complex as that of the camera body. Indeed, production of the body through thixomoulding proved to be such a tough challenge that polycarbonate dies were also prepared in addition to magnesium alloy ones during the development of the EOS-1V.

After much trial and error, Canon succeeded in releasing the EOS-1V as the first EOS camera that makes use of magnesium alloy. The magnesium alloy body is effective in shielding digital noise, and continues to be adopted by all the digital EOS-1 models after the EOS-1V, as well as mid- and high-spec models starting from the EOS 10D. Today, magnesium alloy has become the synonym for high-performance materials for camera bodies, with almost all camera manufacturers employing it for their high-end and professional models. However, these are not the only benefits that magnesium alloy offers. The enhanced robustness of the material makes it possible to increase the sealing strength of the body's seams to achieve unprecedented dust and moisture resistance.

Efforts devoted to pursue the latest technologies in order to cater to our users' needs have resulted in the unique streamline at the top of the body that distinguishes the EOS-1 models from the rest, and led us to enhance the level of performance without compromising the features to be equipped on the camera. Such an attitude toward product development is the secret that enabled the EOS-1 family and the EOS series to win the trust of many professional users.

This is the body of the EOS-1D X before coating is applied. Establishment of the thixomoulding technology has enabled complex curves to be moulded as desired.

*1 The dust- and moisture-resistant feature is not intended to provide guarantee the camera's operation in the rain. Avoid wetting the camera when you are using it on a rainy day.

*2 When the Power Drive Booster PB-E2 is attached.